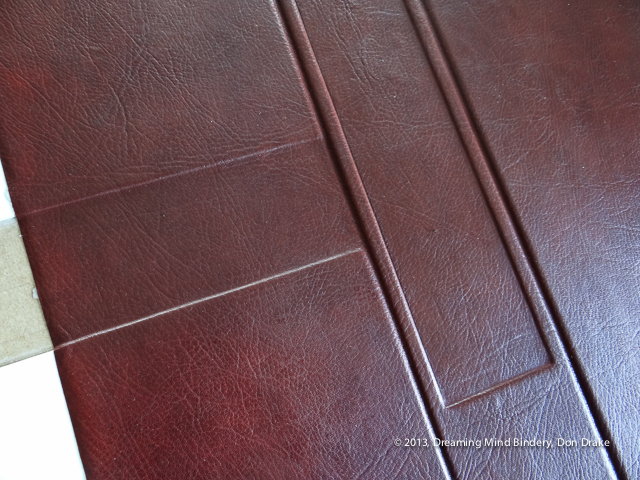

This box will have labels on both the spine and the front cover. I made nice deep debossed beds for the labels since they will be fairly thick; leather over cloth panels.

At this stage, the beds have their final interior dimension (at least in the part that's covered with leather) so I can check the fit of the labels.

If anything was wrong... well, I could remake the labels. Even partially covered, the case is too far along for any serious changes.

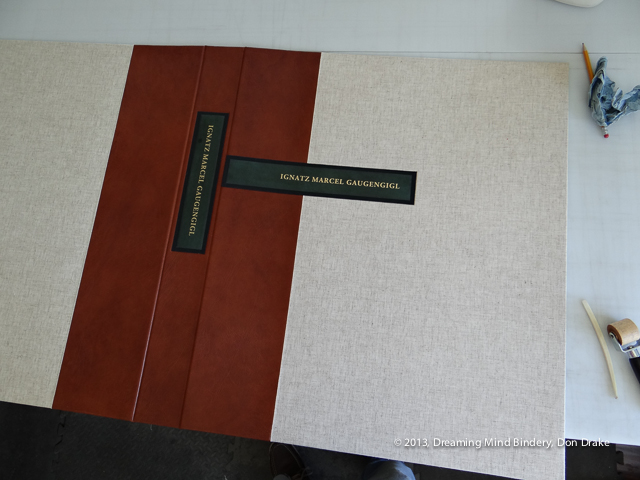

Now with the shells made I can check the fit of the case to the shells. You might expect my spreadsheet to produce a completely reliable fit but things happen sometimes. This was one of those times. It I cut the case boards slightly short so there were no squares at the fore-edge. But since I hadn't laid the cloth down yet I could fix the problem without a complete remake.

To correct the board size I glued bamboo strips at the fore-edge of the boards and sanded them in to match the boards. Once the cloth was laid down and turned the fix was completely invisible.

I'm completely in love with this material pairing. I spent a fair amount of time admiring the deep, clean beds for the labels and the way things are shaping up.

The cover has been counter-lined and are dry so today was the day to stop admiring the materials and put the labels in place.

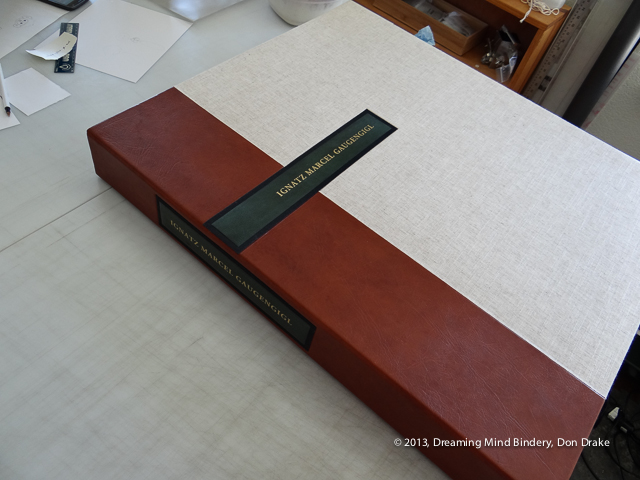

Here's the finished box ready for final assembled. After that, final check and shipment. A large box like this, shipped across the country, requires some serious packaging so there is plenty of work left even after the job is done.

I really enjoyed having this box in the studio and I wanted some of my visitors to take a look. But it's time to package and ship.

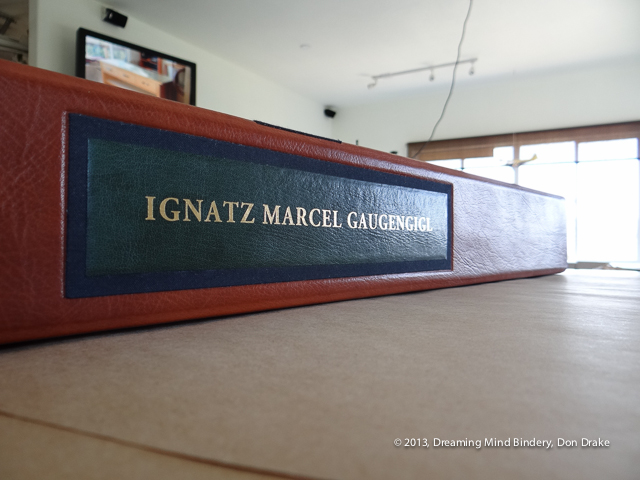

Here's one last detail of the label. I've done labels in a variety of ways. In many cases I've felt they needed something to give the a more finished look than a simple rectangle. This is an especially formal box and I think the framing of the leather on the cloth panels worked well.