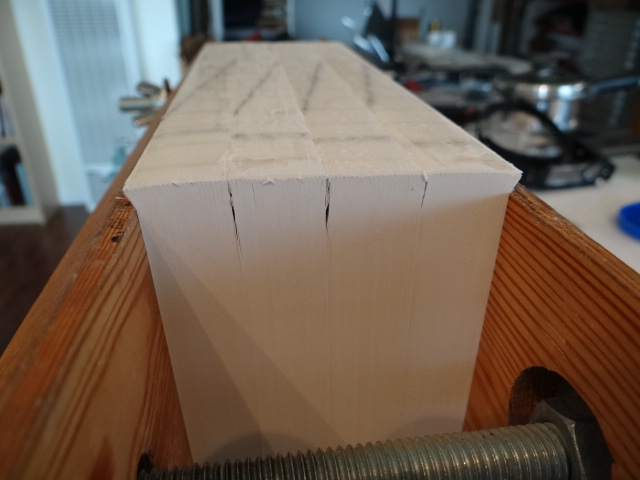

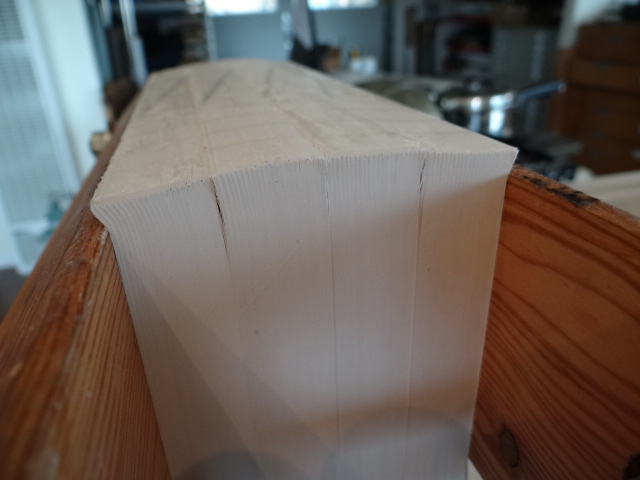

I've taken the covers off the 4 volumes of The Complete Calvin & Hobbes and locked them up in preparation for backing them together. Problem is, the books have some swell and this leaves slight gaps where they meet. The solution for swell is to forward the block but these are so heavy and stiff (and in 4 independent blocks) I can't use any traditional technique.

My solution to the forwarding problem? I'm making a jig that will cradle and shape the spine then I can slide the finishing press down over the block and lock it down.

And here's the result; the back has a more graceful shape and the blocks fit tighter together though their not perfect.

Now I can lay on some mull, put some paper over it, and iron the sandwich down into the hot-glue that binds the blocks. This will create the first level attachment of block to block. and the mull will serve as part of the attachment to the cover boards.

There are a few possible problems that I'm not sure how well I can control.

- The book block is massively heavy???well over 10 pounds??? and is going to need a hugely strong connection to the case or it will tear the book apart.

- The block has unnatural internal hinge points at the break between the original blocks. These may make the book open unevenly.

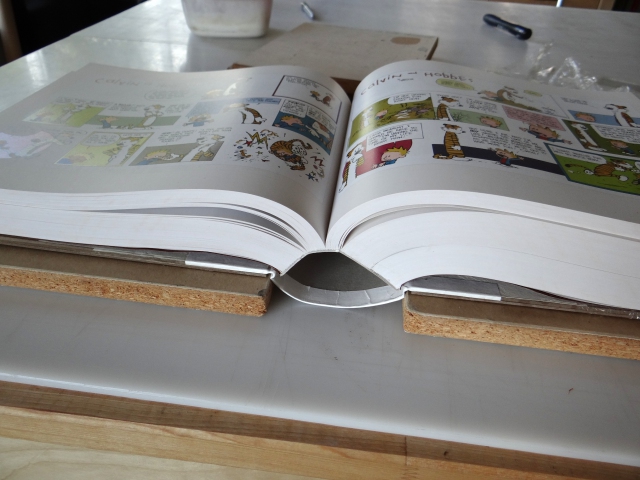

- The original perfect binding lets spine open to an extreme angle rather than throwing up gracefully like a sewn book.

Spine design sketch for Calvin and Hobbes rebinding. This is the process I use to dial in the sizes for hot stamping dies. Once the design is resolved, I drop the layers not needed for the dies, convert to black and save the art to be sent to Owosso.

Commercial perfect bound books like this want to open the spine at an extreme angle but allowing that on such a large book will force a fold into the spine covering material. I could have made a tight back I guess. But here I am. So I'm considering the effect of supporting the book on some lifters to give the material some room to move rather than having it compress and crushed under the weight of the book.

The tentative plan is to include the lifters in the slipcase.

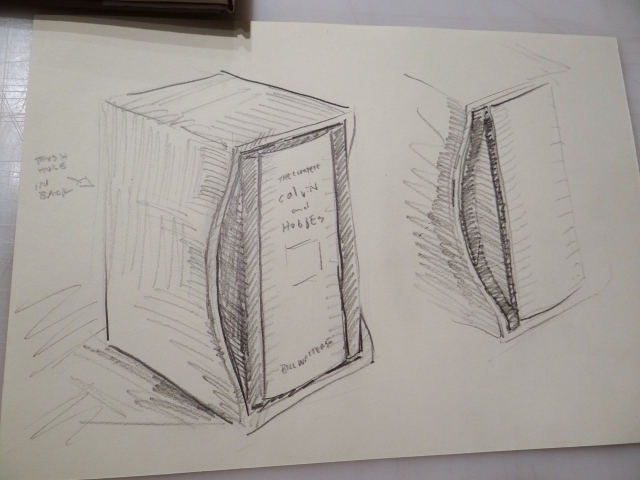

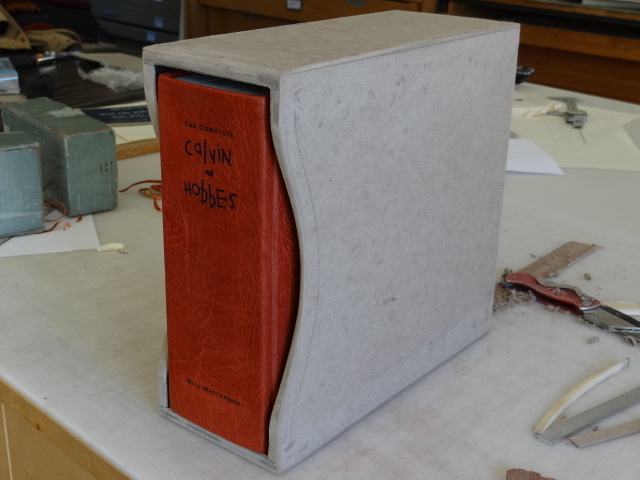

Here's a preliminary design sketch for the box with both the book and a wrapper that would double as a cradle for reading the book. The box would have swept back fore edges so you would grip the wrapper/cradle and the book, removing them from the box as a unit. The box would also have a hole in the back so you could push to aid in removal of the heavy content.

The cradle would be in the proper position to open with the book so there wouldn't be any figuring out how to arrange things.

It's going to take a lot of hand strength to manage this thing!

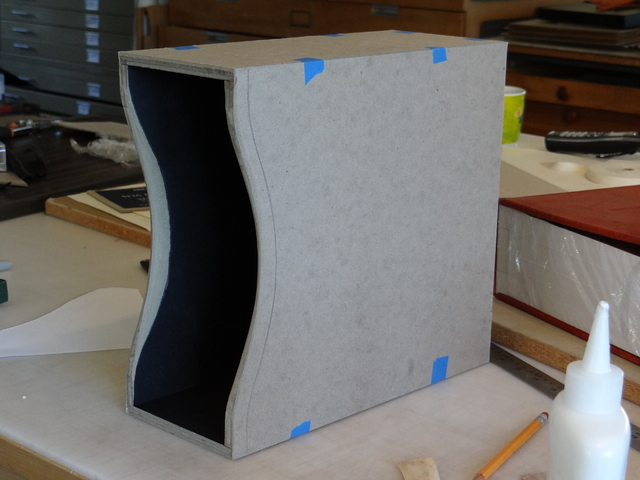

The book this slip case will contain is so large and heavy I really needed to beef up the scale of the box. Both strength and design considerations demanded it.

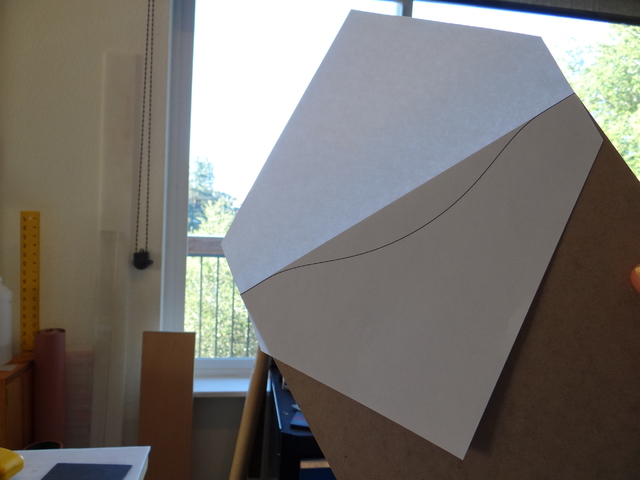

It might be a bit difficult to get the materials to sculpt smoothly around this deep curve but there isn't much choice. Even exposing 1" of the book, as this curve does, seems like a minimal grip area to pull this amount of weight.

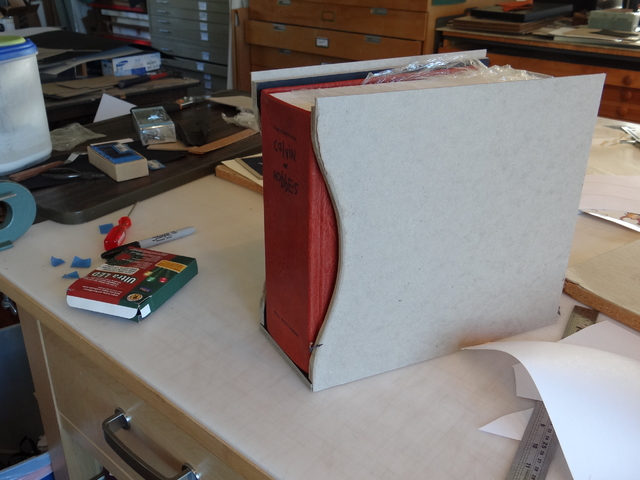

After rough shaping of the slip case side walls, it's time for another check for fit and design.

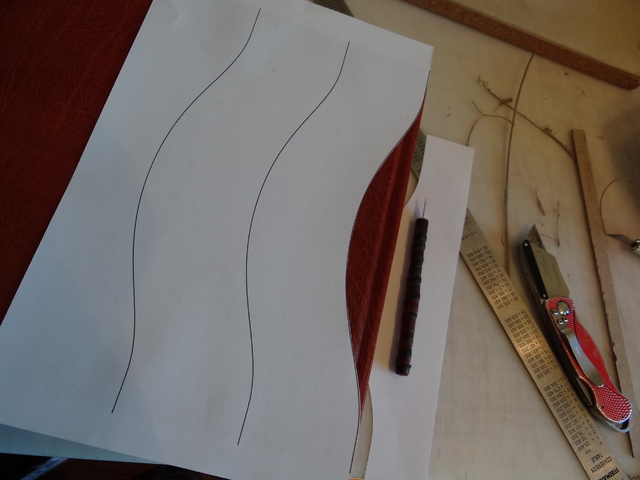

Fitting a cutting template to a slip case part

Sculpting these fore edges should help lighten up the overall effect of the piece. Also it may allow a little more room for fingers when removing the book.

This project is rife with design/function duality.

Everything went together fine. Covering it is going to be a little tricky.

This is the first time I've really been able to see how the book and box will function together. I'm happy!