I've got a bit of overflow from my cloth storage wrack and it's taking up floorspace that could be put to better use.

All part of the settling-in process in a new studio.

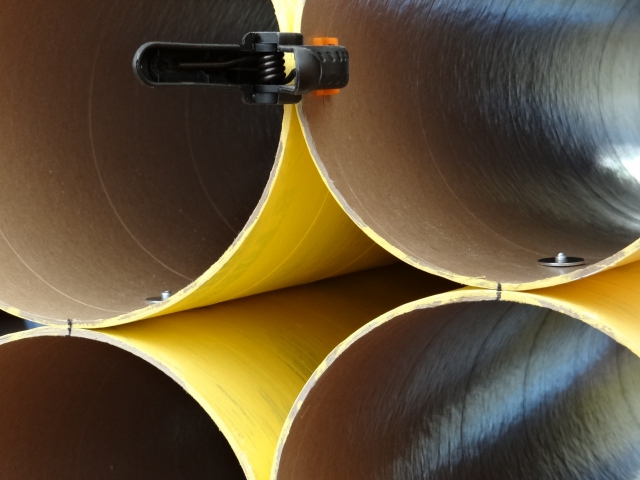

There is a corner above one of the flat files that will give me about 5' of vertical space for a new roll storage unit. After thinking about my options, I think the quickest thing to make (and possibly the least expensive) will be a cubby-system made from large diameter cardboard tubes.

After some research I found I could get 8" concrete pier casting forms from my local home improvement center.

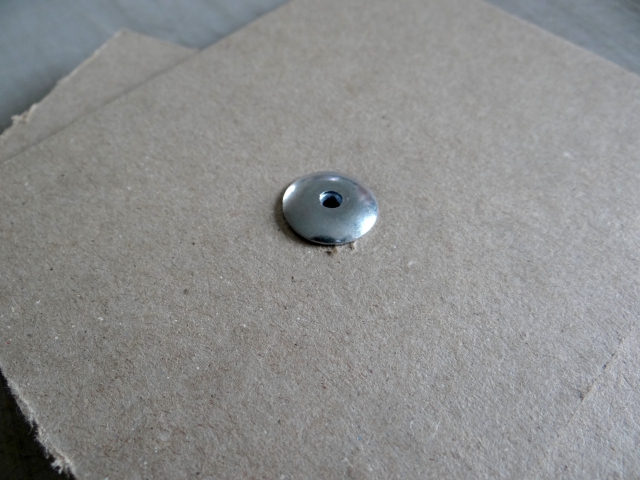

I found pop rivets that will be perfect for this project today. Large flange with a 3/8" grip and a 5/32" shaft. Big and solid!

With these attachments I think I can get away with one rivet at each end of the tubes. That should make construction quicker and easier.

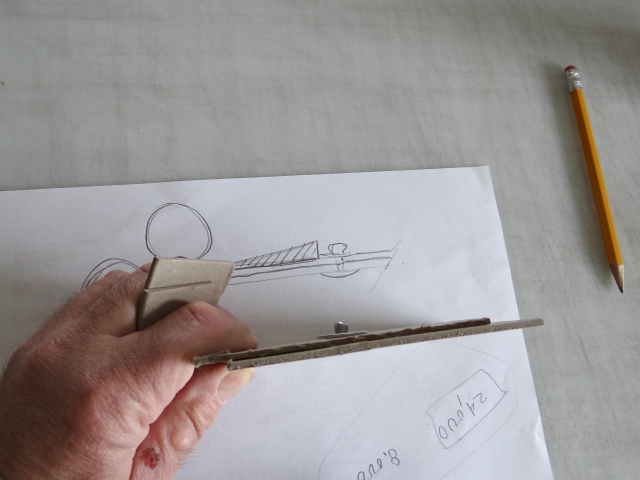

![Measuring the extension on the back side of a large flange pop rivet. The rivet is being tested for the construction of a tube storage system

![A diagram showing the riveting plan for a roll material storage system][1]

The opposite side of the rivet poses the risk of damage to the material. The fender washer provides an excellent anchor for the back but the rivet extends 0.2" past the washer. The tubes are 8" in diameter and the largest roll of cloth is 6". So there will be plenty of clearance in a typical situation. What about when multiple roles are stored together?

Here's a diagram showing the proposed positioning of the rivets. The potentially damaging nubs will be at the top and half way up one side. This positioning helps minimize the risk of material damage but reduced-risk is not no-risk. Maximizing storage will again put the material at risk.

Here's a diagram showing the proposed positioning of the rivets. The potentially damaging nubs will be at the top and half way up one side. This positioning helps minimize the risk of material damage but reduced-risk is not no-risk. Maximizing storage will again put the material at risk.

A diagram showing the riveting plan for a roll material storage system

Here is plan to eliminate the risk of damage from the rivet nubs. If I make small wedges that keep the rolls from impacting the metal nubs, the system should be safe in all cases. I'm not sure what to make the wedges out of. I have plenty of scrap Davey board I could laminate to the proper thickness. Or I could get some scrap wood out of the rack and do some bandsaw work...

All in all, a fussy solution. But well worth the effort to save expensive materials.

Drilling holes for rivets in the cardboard tubes during construction of a roll material storage unit.

Assembling the first trio of cardboard tubes during construction of a roll material storage unit.

Assembling the first bank of six cardboard tubes during construction of a roll material storage unit.