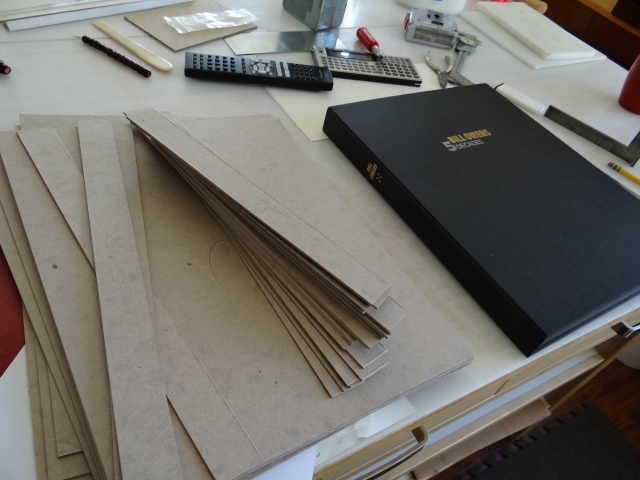

This is my favorite stage of box assembly; all the double walls prepared and stacked up before constructing the shell. I like the precision and pattern the pieces make.

A satisfying scattering of debris. Evidence of many projects moved from pending to active.

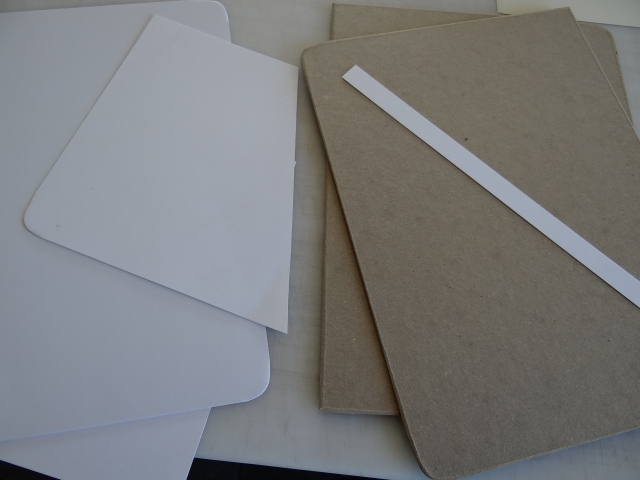

These are parts for a typical business portfolio. I need to zip this through the studio. It was an order that came in before the turn of the year but it wasn't required for gift delivery so it was postponed. Now it's time to catch up.

Box parts for the Bill Owens 5 Decades Portfolio

I've had a no-deadline order for quite a while to make another box for one of the Bill Owens picture sets. It's time to clear this standing project off the list.

When Geir Jordahl heard I was going to bring the box to the bench, he ordered two for himself.

Off we go!

The leather has been pasted down on the portfolio

I forgot this portfolio needs a card pocket on the inside corner pocket. So, I pulled the leather and chased this piece along after the case.

The burgundy Iris bookcloth I'm using for the liners in this portfolio has a nasty curl-memory. This seems to be typical of the few colors of Iris I have. Darned hard to work with in this state.

I have a new secret weapon to deal with curled materials. A cheap steamer! Just a minute and this cloth settles out nicely. It's a bit surprising but the effect is permanent. Once the moisture content normalizes again the cloth stay reasonably flat.

Now with the cloth relaxed, the process of cutting the parts and covering the liner boards is pretty straight forward.

Laying out the cover inside a goat skin

The goatskin is pared and ready to paste. This shows he paring for the rounded portfolio corners

The goatskin with the layout done and ready to trim out

Here are the liners after they've been covered and trimmer. Next step, to turn the edges.

Of course, assembling the base-liner and pocket gets taken care of in this step.